I was scouring back though my

brewing books trying to get motivation for a recipe, something different. In Brewing

with Wheat, by Stan Hieronymus, I came across a recipe for a Peeterman, a

type of wheat beer. It was bigger, sometimes

darker and usually drunk fairly young.

It was similar to a Blanche de Louvain where “One third of the wort was

brewed with hops.”

In that same section Hieronymus

discusses how the beers from around Leuven (Louvain), Belgium were made. One third of the wort was boiled with hops

and the other two-thirds were ran straight into the fermenters. These beers were tart to sour and so I

thought, that this might be a perfect chance to make a modern take on this beer

through kettle souring a portion. I

wanted to make a beer that was sour, but not too sour, and that didn’t have the

chance to pick up any nasties.

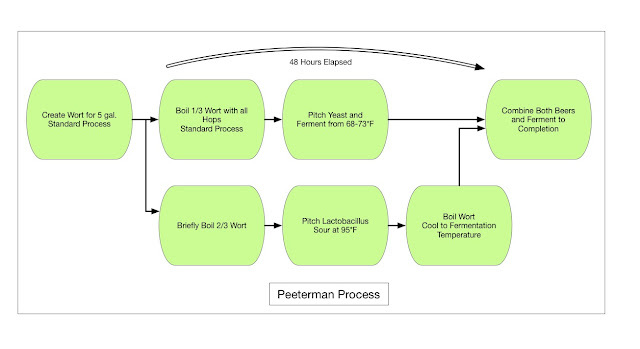

My idea was that I would make

the wort, run off a third, and boil it with enough hops to contribute ~10 IBU

to the entire volume. The remaining

two-thirds I would run off into a separate kettle and sour. My idea of a modern take was to pre-boil the

two-thirds wort for a few minutes and then pitch a 3 GoodBelly shots (Lactobacillus

Plantarum) and let this sour for two days at 95*F. Back to the first third, I treated it just as

I would any of my beers, boiling it with the hops, cooling it to pitching

temperatures, and then pitching yeast. I

would let this beer ferment for 2 days while the other portion was souring, as

a kind of starter akin to the sake process, except on the second day I would

boil the soured wort for 15 minutes and pour it back into the fermenting

portion. Get all of that? It might take a flow chart…

My recipe looked like this:

Recipe: Peeterman

Style: Witbier

TYPE: All Grain

Date: 31 Mar 16

Batch Size (fermenter): 5.50

gal

Estimated OG: 1.065 SG

Estimated Color: 5.5 SRM

Estimated IBU: 10.5 IBUs

Brewhouse Efficiency: 70.00 %

Boil Time: 75 Minutes

Ingredients:

6.00 ml Lactic Acid (Mash 60.0 mins)

13.0 oz Rice Hulls (0.0 SRM) 4.9 %

7 lbs 1.4 oz Pilsner (2 Row) Bel (1.7 SRM) 42.8 %

7 lbs 1.4 oz Wheat, Raw (2.0 SRM) 42.8 %

15.1 oz Oats, Flaked (1.0 SRM) 5.7 %

7.6 oz Aromatic Malt (26.0 SRM) 2.9 %

2.5 oz Buckwheat, Raw (2.0 SRM) 1.0 %

16.00 g Crystal [6.00 %] - Boil 75.0 min 10.5 IBUs

0.50 tsp Yeast Nutrient (Boil 10.0 mins)

1.0 pkg Belgian Wheat Yeast (Wyeast Labs

#3942)

Mash Schedule: Single

Infusion, Batch Sparge

Mash In Add 21.92 qt of water at 163.6 F 150.0 F 60 min

Sparge: Batch sparge with 2

steps (Drain mash tun , 3.52gal) of 185.0 F water

Fermentation started at 68

degrees and finished at 73.

The execution of this recipe

was a disaster. Like anything for the

first time, I was running around trying to figure out what the hell I needed to

do next. I had also convinced myself

that I could do both batches at the same time.

This led to a couple of errors on brew day, not oxygenating the wort and

totally missing my numbers.

Missing the oxygen didn’t

turn out to be a big deal, but I had never used this much raw wheat in a batch,

and I totally missed my numbers. What

was supposed to be a big, sweet finishing beer, ended up at 1.043 preboil and

1.059 in the smaller one-third portion.

By calculation, I figured I would have somewhere around a 1.050 OG

beer. I chalked it up to a lesson, and

moved on.

From there the beer went on

great. The sour portion acidified down

to 3.5 pH by strip, which is a little better than measuring it with my

tongue. The yeast in the clean portion

ripped through the wort and was already slowing down when I combined the two

beers. It finished out nicely, albeit a

little higher, at 1.012, approximately 5.0% ABV, and 3.6 pH.

So even though this was

probably nothing like a Peeterman, it turned out a mighty fine beer. More so than other kettle soured beers that I

have tasted and made, this beer had a lot of character from the Saccharomyces

yeast. This was a nice welcome to a beer

that could have just been sour. The

finished beer had a good sour finish, but you could still catch that nice

Belgian character with a bit of bubble gum and stone fruit. I could not detect any major flaws, but as

the beer became warm there was an interesting phenolic note, that I don’t know

if I could describe. No one else who

tasted the beer was able to detect it.

If there was anything I would describe it as, it would be like a burnt

rubber or plastic, but very, very faint.

The lesson I’ve drawn from

this experience is one of blending, or you might call it portioning. It might be the best way to create a sour

beer. Aside from making a separate acid

beer and blending it with others, I think that splitting a beer like this makes

it a bit easier depending on your system, process, and space available. You don’t have as much control as you would

blending an acid beer, but you could be pretty exacting once you worked the

percentages out for your particular desires or recipe. I will definitely do this again in the future,

possibly leaving the sour portion un-boiled.

Maybe I’ll even do a cereal mash for all that raw wheat!